More Than Just Rolling Stock

Wheels are one of the most transformative components you can select for your vehicle. Far more than just a place to mount your tires, they are a critical intersection of performance, safety, and aesthetics.

The right set of wheels can dramatically enhance your car’s handling, improve fuel efficiency, and define its visual identity. Conversely, an improper choice can compromise safety and detract from the overall driving experience.

This comprehensive guide will navigate the intricate world of automotive wheels, providing the foundational knowledge needed to understand their function, construction, and how to select the perfect set for your needs.

A GMC pickup undergoing wheel service at a Comtires tire shop, emphasizing how proper maintenance enhances handling and vehicle performance.

The Unsung Hero of Your Vehicle’s Performance and Aesthetics

Every aspect of your vehicle’s connection to the road is transmitted through its wheels. They bear the vehicle’s weight, endure forces from acceleration and braking, and play a pivotal role in the responsiveness of your steering and suspension.

From a performance perspective, their weight and rigidity directly influence handling and comfort. Aesthetically, their designs are a primary factor in a vehicle’s curb appeal. Understanding these dual roles is the first step toward making an informed decision.

The Foundation: Primary Automotive Wheel Types

The journey to finding the right wheels begins with understanding the fundamental types available, each offering distinct advantages based on material and manufacturing.

Different wheel types are designed for specific transportation needs, from passenger cars to light trucks.

Steel Wheels: The Reliable Workhorse

Often found on base model vehicles, commercial trucks, and as spares, steel wheels are the industry’s durable standard. Made from a heavy steel alloy, they are incredibly strong and resistant to damage from road hazards.

While their weight can negatively impact handling and fuel efficiency, their low cost and ease of repair make them a practical, no-frills choice for utilitarian applications.

Alloy Wheels: The Modern Standard for Cars and Light Trucks

Alloy wheels, typically made from a mixture of aluminum and other metals, represent the modern benchmark for passenger vehicles. They are significantly lighter than their steel counterparts, which reduces “unsprung weight” the mass not supported by the vehicle’s suspension.

This reduction allows the suspension to react more quickly to road imperfections, improving both handling and ride comfort. Furthermore, the malleability of aluminum alloys allows for a vast array of intricate and visually appealing designs.

Aftermarket Wheels: Customization and Enhancement

The aftermarket offers an expansive world of wheels for enthusiasts seeking to personalize their vehicle or upgrade its performance.

These options provide a wide spectrum of sizes, styles, materials, and manufacturing methods, allowing drivers to tailor their choice to specific driving habits, from daily commuting to competitive track use. Investing time in research is crucial when exploring aftermarket options to ensure proper fitment and safety.

The Heart of Performance: Wheel Materials and Manufacturing Processes

The way a wheel is made is just as important as the material it’s made from. The manufacturing process dictates its strength, weight, and cost.

Cast Wheels: The Traditional and Accessible Choice

Casting is the most common and cost-effective method for producing alloy wheels. The process involves pouring molten aluminum into a mold.

This technique allows for complex designs but can result in a wheel that is heavier and less dense than those made by other methods. While perfectly suitable for most daily driving conditions, cast wheels may be more susceptible to cracking from severe impacts.

Rotary Forged (Flow Formed) Wheels: Bridging the Gap Between Strength and Affordability

Rotary forging, also known as flow forming, is a hybrid manufacturing process.

- It starts with a low-pressure cast wheel face,

- which is then spun at high speed while heated.

- Steel rollers apply pressure to the barrel, stretching and compressing the aluminum.

This process realigns the grain structure of the metal, resulting in a barrel that is lighter and significantly stronger than a traditional cast wheel, offering an excellent balance of performance and price.

Forged Wheels: The Apex of Strength and Lightweight Performance

Forging is the pinnacle of wheel manufacturing. A solid billet of aluminum alloy is subjected to immense heat and pressure, forcing the metal into its final shape. This process creates an incredibly dense and strong wheel with a superior grain structure.

Forged wheels offer the highest strength-to-weight ratio, providing exceptional performance and resistance to damage. Their complexity and high cost reserve them primarily for high-performance vehicles and serious enthusiasts.

Decoding the Numbers: Key Wheel Specifications and Fitment

Choosing a wheel isn’t just about style; precise fitment is critical for safety and performance. Every wheel has a set of specifications that must match your vehicle.

Bolt Pattern (PCD): The First Compatibility Check

The Pitch Circle Diameter (PCD), or bolt pattern, is the number of lug nut holes and the diameter of the circle they form.

A pattern like “5×114.3” means five lug holes on a 114.3mm diameter circle. This must exactly match your vehicle’s hub for the wheel to be mounted.

Wheel Diameter and Width: Sizing Up Your Ride

Diameter (the wheel’s height) and width are the most visible specifications. While larger diameters can enhance appearance, they often require lower-profile tires, which can lead to a harsher ride.

Wheel width affects which tires can be safely mounted and influences the vehicle’s handling characteristics.

Wheel Offset (ET): Understanding Your Wheel’s Stance

Offset (measured in millimeters) is the distance from the wheel’s mounting surface to its centerline. A positive offset tucks the wheel into the fender, while a negative offset pushes it outward.

Incorrect offset can cause clearance issues with the suspension or fenders, negatively impacting steering and safety.

Hub Diameter and Center Bore: Ensuring a Snug Fit

The center bore is the large hole in the middle of the wheel that fits over the vehicle’s hub. A hub-centric fit, where the bore and hub diameters match perfectly, is ideal for preventing vibrations.

Lug-centric wheels, which are centered by the lug nuts, may require hub-centric rings to ensure a smooth ride.

Load Index and Speed Rating: Safety and Performance Limits

Every wheel has a maximum load rating it can safely support. It is imperative to choose wheels with a load index that meets or exceeds your vehicle’s specifications, especially for trucks and SUVs.

Speed ratings indicate the maximum safe speed for which the wheel is designed.

Tire Compatibility: A Wheel’s Best Friend

The relationship between wheels and tires is symbiotic. The wheel’s width dictates the range of tire sizes that can be safely installed. It’s crucial to check that your desired wheels are compatible with appropriate tires that meet your vehicle’s load and speed requirements.

Proper tire compatibility is essential for wheel performance. Every wheel must match the tire’s width, diameter, and load rating to ensure stability and safety. Before purchasing new wheels, verify tire fitment with a trusted supplier or certified tire shop to avoid vibration or premature wear.

Beyond Function: Aesthetics and Wheel Design

While function is paramount, the visual appeal of wheels is undeniable. The right design can completely redefine a vehicle’s character.

The Visual Impact: How Wheels Define Your Vehicle’s Look

Wheel designs from classic five-spoke patterns to intricate mesh styles offer a powerful way to express personal taste.

The finish, whether it’s painted, polished, chrome, or matte, adds another layer of customization. The combination of design and finish can make a vehicle look more aggressive, luxurious, or sporty.

Functional Design Considerations: Balancing Style with Safety

Good design isn’t just about looks. The number and shape of the spokes can affect a wheel’s weight and strength. Open-spoke designs can improve airflow to the brakes, helping to dissipate heat during spirited driving.

However, it’s vital to ensure any chosen design maintains the structural integrity required for your vehicle and driving style.

The Ultimate Decision: Choosing Your Perfect Set

With a solid understanding of the fundamentals, you can now approach the selection process strategically.

Define Your Priorities: Performance, Aesthetics, or Budget?

Be honest about what matters most. Are you seeking maximum performance, a specific look, or the best value? Your answer will guide you toward the right type, material, and manufacturing process.

Match Wheels to Your Vehicle and Driving Habits

The ideal wheel for a daily commuter is different from that for an off-road truck or a track-focused sports car. Consider your typical road conditions and driving style to ensure your choice enhances your experience, from comfort to efficiency.

Researching and Verifying Fitment (with trusted suppliers)

Always double-check that the wheels you want will fit your vehicle without any issue. Reputable suppliers provide tools and expertise to verify compatibility, preventing costly mistakes and ensuring a safe installation.

Budgeting for Your Investment: Quality vs. Price

While it’s tempting to opt for the cheapest option, remember that wheels are a critical safety component. Investing in a quality set from a reputable brand ensures better manufacturing, durability, and peace of mind.

Maintaining Your Investment: Care and Related Considerations

Proper care will extend the life and appearance of your wheels and ensure continued safety.

Basic Wheel Care and Cleaning

Regularly clean your wheels with pH-neutral cleaners to remove brake dust and road grime, which can damage the finish over time.

A protective wax or ceramic coating can make future cleaning easier. Always check their condition for any signs of visible damage.

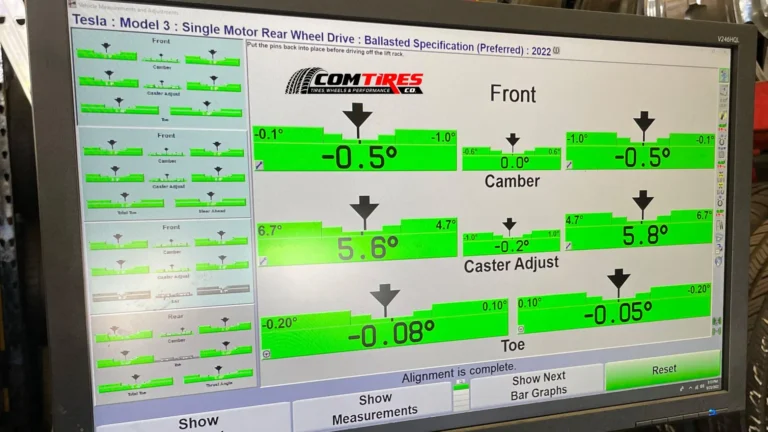

The Critical Role of Wheel Alignment

Proper wheel alignment is crucial for preventing uneven tire wear and ensuring predictable steering. An impact that doesn’t visibly damage a wheel can still knock out the alignment, so it’s wise to have it checked periodically.

Addressing Wheel Damage and Alloy Wheel Repair

Inspect your wheels for cracks, bends, or curb rash. Minor cosmetic damage on alloy wheels can often be repaired, but structural damage is a serious safety issue that may require replacement.

If you notice any vibration or change in steering, have your wheels and tires inspected immediately.

Regular inspections and professional alignments at certified tire shops help maintain optimal wheel and tire performance.

Conclusion: Rolling Forward with Confidence

Recap: The Journey to Your Perfect Set

From understanding materials and manufacturing to decoding fitment and maintenance, you now have the essential knowledge to make confident wheel decisions. The right wheels don’t just enhance appearance they directly impact safety, handling, and efficiency.

Final Encouragement & Call to Action

Ready to upgrade your wheels? Visit a certified tire shop or explore our complete guide to wheels for expert recommendations, fitment tips Comtires. Rolling forward with the right set means combining performance, safety, and style in one perfect match.

To continue enhancing your vehicle’s care and uncover practices that extend its lifespan, check out our complementary article: The Ultimate Guide to Wheel Alignment: Master Your Vehicle’s Performance & Longevity

FAQs

What is the best guide to wheels?

The Ultimate Guide to Wheels by Comtires is your complete reference for understanding wheel types, materials, and fitment.

It explains how to match the right tires, interpret wheel specifications, and maintain your wheels for long-term performance and safety.

What are the different types of wheels and their uses?

There are three primary wheel types steel, alloy, and forged.

- Steel wheels: durable and ideal for work vehicles or harsh conditions.

- Alloy wheels: lightweight, perfect for daily driving and improved handling.

- Forged wheels: ultra-strong and light, built for performance vehicles.

Each offers unique advantages depending on your driving habits and budget.

How do I choose the right wheel for my vehicle or project?

Start by defining your priorities: performance, aesthetics, or cost. Check the bolt pattern, width, and offset to ensure proper fitment.

Match your wheel choice with tire compatibility and confirm specifications with a trusted supplier like Comtires to guarantee safety and precision.

What materials are commonly used in manufacturing wheels?

Most modern wheels are made from steel or aluminum alloys.

- Cast aluminum is affordable and allows for creative designs.

- Forged aluminum provides superior strength with minimal weight.

Some high-end or specialized wheels use magnesium or carbon fiber for ultimate performance, though they come at a premium cost.